Technology

Greener Day Solutions is always focusing on independent technology in dewatering systems. We are proud to represent a new generation of sludge

dewatering technology with the Multi-Disc Screw Press. Dewatering substantially reduces sludge volume and therefore reduces transportation and disposal costs.

Multi-Disc Screw Press

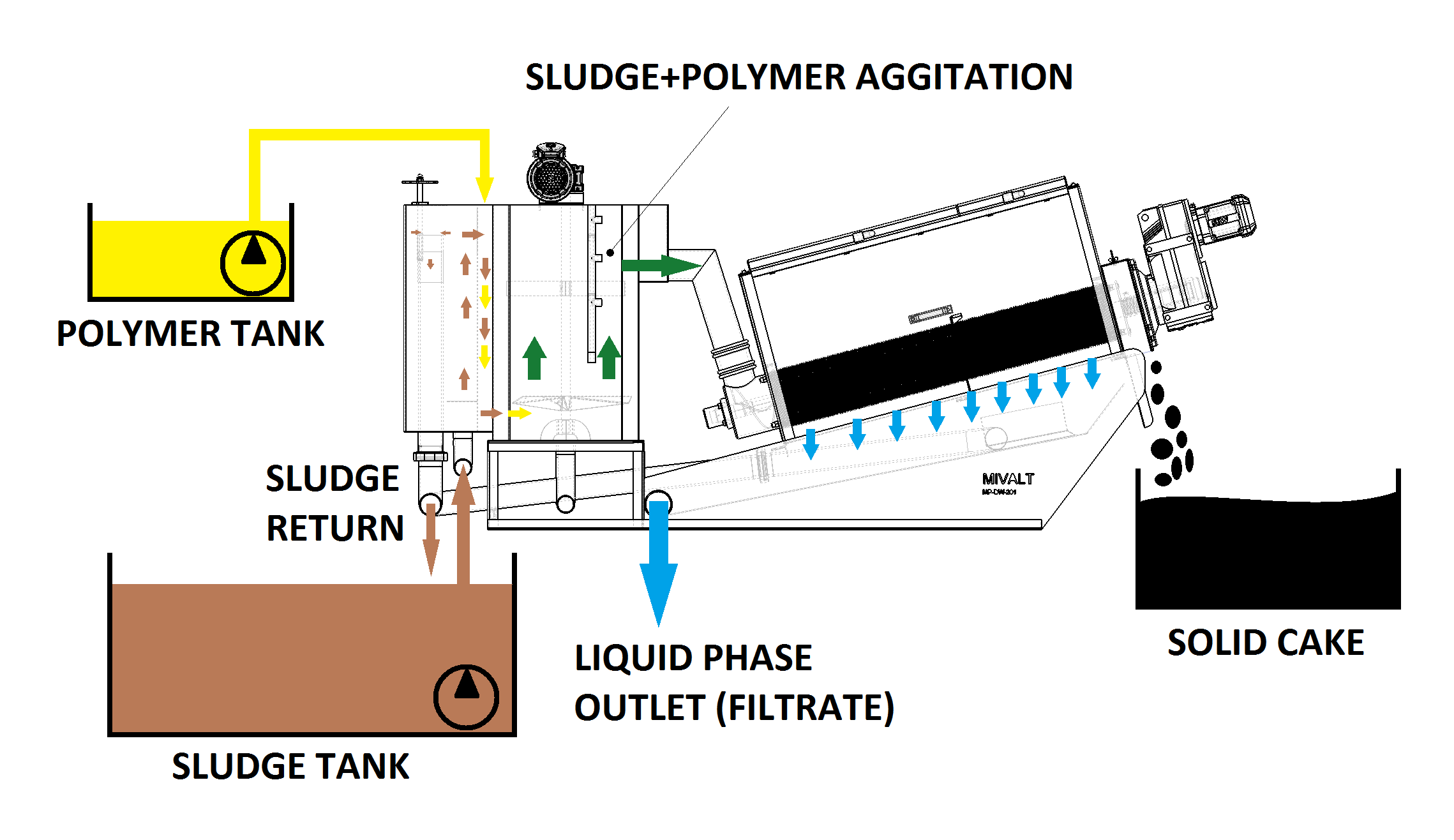

Dewatering Process

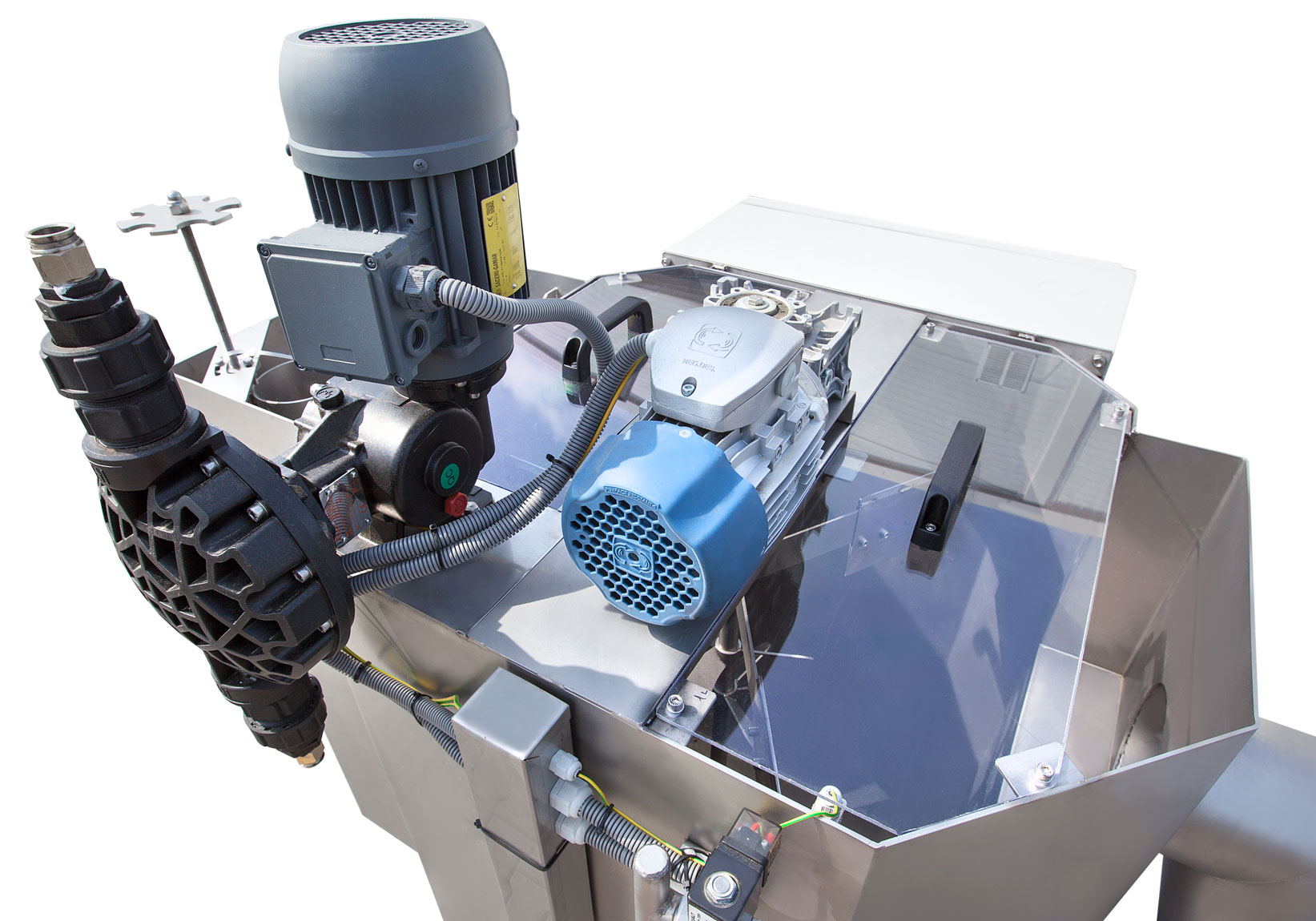

Sludge water is carried into the Multi-Disc Screw Press using a feed pump. The feed pump forces sludge water into the first inlet chamber, where the flow to the other part of press is optimized by means of overflow. When sludge water leaves the inlet chamber and enters the mixing chamber, a flocculant/polymer is added which makes solid particles aggregate into “flock”.

The flocking process occurs in the mixing chamber while sludge water is slowly mixed with the flocculant by a bladed shaft. The flocked sludge water is then carried into the screw cylinder. The variable pitch of the helix screw is completed with both fixed and floating rings acting as a self-cleaning filter.

Greener Day Solutions is always focusing on independent technology in dewatering systems. Our Multi-Disc Screw Press is much more advanced than belt presses and centrifuges. It features a wide range of applications, is fully automatic, has low clogging technology, has low energy consumption and is simple to operate with lower maintenance costs.

Some of the benefits of the Multi-Disc Screw Press are:

Low energy usage, automated mode, economical operation and smaller footprint than other technologies.

More Questions?

Contact Us

What Sets Us Apart

Innovation

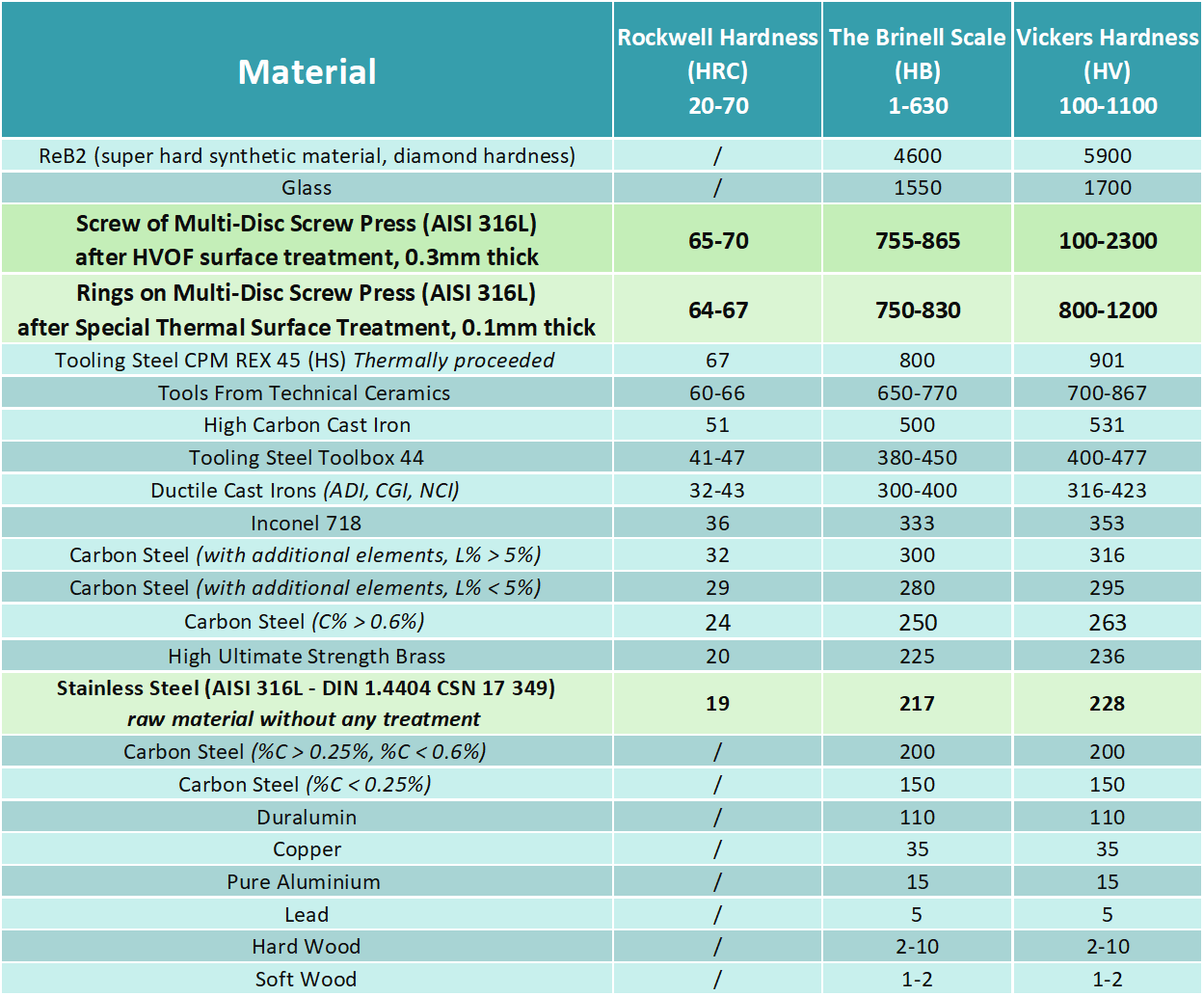

We are the only company in the industry using 316 Grade Stainless Steel and Special Thermal Surface Technology. This ensures abrasion resistance, increased hardness and resistance to

wear and tear. This also provides the necessary resistance to corrosion from the materials that come in contact from aggressive sludge water.

Hardness Overview

The Multi-Disc Screw Press is made of X5CrNi18-10 (1.4301/SS304) Stainless Steel. The screw and the discs are made of X2CrNiMo17-2 (1.4404/SS316) Stainless Steel and are treated with a Special Thermal Surface Technology which increases corrosion resistance and extends the wear life. The screw is coated with 2mm of Tungsten Carbide coating which increases the operating life by 50%.

This chart shows a hardness overview of the Multi-Disc Screw Press components against normally used materials. The technology used on our press ensures the metal surfaces have the same hardness so the wear will be equal for the life of the press.

Thicken Sludge

Sludge-water is a product of the mechanical, biological and chemical treatment of wastewater in wastewater treatment plants. Our dewatering screw press, which serves to thicken sludge water to 15-30% dry-matter content, can provide efficient de-sludging.

In terms of quality, it surpasses traditional sedimentation sludge removal. Our dewatering/thickening screw presses are designed to be used in wastewater treatment plants and can also be used for thickening both industrial water and wastewater in food processing operations. If a dewatering press is already incorporated into a WWTP, design and costs related to the construction of sedimentation tanks are eliminated as this equipment can also be used for thickening secondary sludge directly from activation.

Benefits of this MD Screw Press:

• Low energy use

• Simple installation and operation

• 0.5–5% sludge at inlet and 15–30% sludge at outlet

• Low noise and vibration levels

• Wide use applications

• Automated mode

• Affordable spare parts

• Low transport weight

• Economical operation and a smaller footprint

• High quality workmanship, manufactured in the Czech Republic

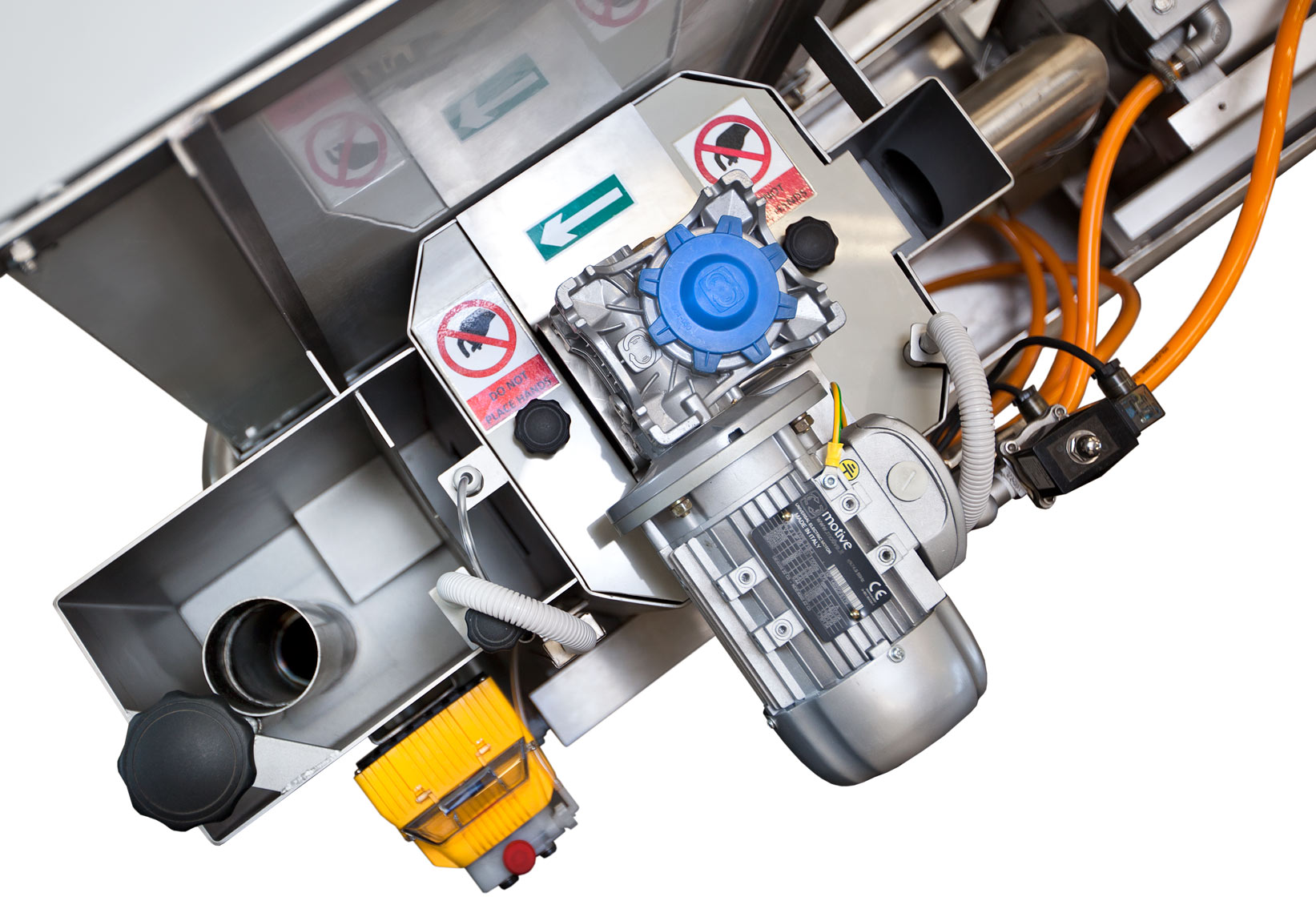

Operation

These presses can operate in an automatic mode reducing labor costs. The operator can check the status of the equipment and make the necessary adjustments for optimal performance using the PLC touch screen display. The main screw motor is connected to a SEW-EURODRIVE gearbox and thanks to the front transmission achieves 7 rpm. The motor is connected via a frequency inverter, which makes it possible to further accelerate/slow down the screw. These presses can also run in manual mode, where each component can be manually turned on/off by means of the control display.